In the picture, from the left: Kristo Piksar, CTO and Nadežda Dementyeva, Managing Director.

New production equipment worth two million euros was launched at Inission Tallinn Mechanical Plant, which will help increase the production capacity of sheet metal products by 20%. The investment includes four production machines, including a robot work centre that is unique in the Baltics.

According to Nadežda Dementyeva, Managing Director at Inission Tallinn, the focus of the company celebrating its 15th birthday this year will be on automation, robotization and digitalization of production.

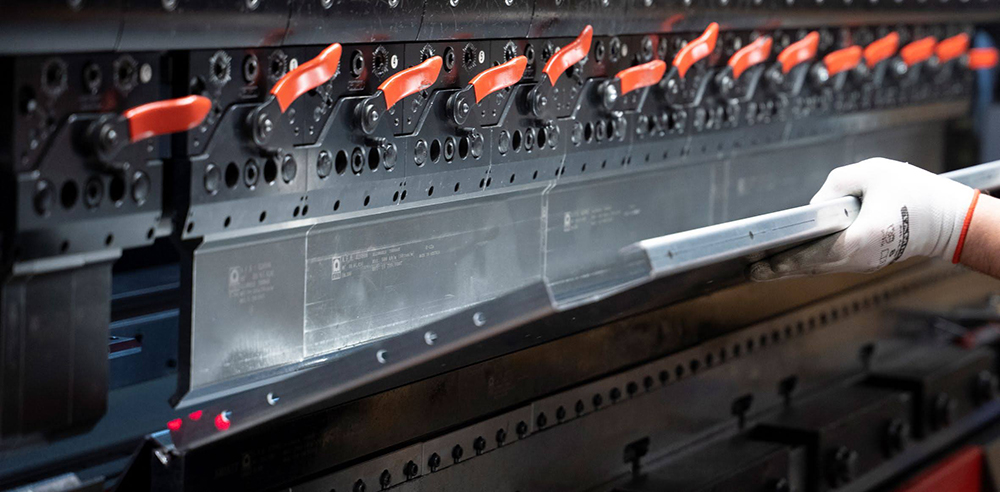

– The major investment will increase the production capacity of the Lagedi plant engaged in sheet metal processing and significantly expand our product portfolio. The new Amada and LVD devices represent the latest in industrial technology and are part of the concept smart industry. The factory’s production is used in a variety of fields, including computers, servers, power substations and cabinets and other products requiring thin metal.

Among the new additions is an Amada Combilaser equipped with an automatic carousel tool warehouse, the first of its kind, not only in the Baltics but also within the Inission group. The device uses automatic stamp blade exchange robotic arms, which serve a carousel warehouse with more than 400 tools.

According to Kristo Piksar, Chief Technology Officer at Inission Tallinn, the new production equipment will significantly increase the efficiency.

– It´s possible to work on fully automated lines for up to a week, without human intervention, until the materials run out.

Monitoring of the robot work centre is carried out by cameras from behind the office desktop, where it is also possible to monitor the efficiency of machines in real time. Previously, it took up to five hours to prepare the program, depending on the complexity of the product, which means significant time savings.

In addition to the robots available at the factory, a new LVD robot centre was also acquired.

– Artificial intelligence analyses the detail produced and creates a solution within a couple of minutes, which is the best way to bend that detail by selecting the tools and the order in which they are used. In doing so, artificial intelligence also considers how the robot’s movement in bending would be the most efficient and energy-efficient, says Piksar, explaining the logic of using an artificial hive in production.

Preliminary work on the introduction of new machines took several months, during which all the infrastructure, including electrical and compressed air systems, was rebuilt. The number of employees remains the same but working with machines required separate training with representatives of manufacturers in England and Belgium.

Inission Tallinn has been operating in Estonia for 15 years and has increased sales volume and turnover more than twice in the last two years. Estonian factories export their products to the European, Asian and US markets.

Inission Tallinn OÜ belongs to the Inission AB group listed on the Nasdaq Stockholm Stock Exchange, with nine factories located in Sweden, Finland, Norway and Estonia. The company’s Estonian factories are in Tallinn and Lagedi. The Tallinn factory produces electronics and electromechanics – circuit boards, parts of equipment and larger integrated solutions for electronics. The Lagedi mechanical plant produces complex and high-precision products from thin sheet metal. Estonian factories employ up to 180 employees. Lagedi previously operated under the names Hyrles OÜ and HY-Tech Comp.

For more information:

Nadežda Dementjeva, Managing Director, Tallinn/Lagedi

[email protected]

+372 539 67467

About Inission

Inission is a total supplier of customized manufacturing services and products in advanced industrial electronics and mechanics. Our services cover the entire product life cycle, from development and design to industrialization, volume production and aftermarket services. Inission has operations in Sweden, Norway, Finland, Estonia, Italy, the USA, and Tunisia. Inission has a strong value-driven corporate culture of entrepreneurship and passion, which has 2023 resulted in a turnover of approx. SEK 2,2 billion with approx. 1 070 employees. Inission is listed on Nasdaq First North Growth Market. Inission’s offer is divided into two business areas; Contract manufacturing of electronic and mechanical products under the brand Inission and Power electronics and systems under the brand Enedo. Reports are archived at www.inission.com/en.

Inission AB, Lantvärnsgatan 4, 652 21 Karlstad

company registration number 556747–1890

The information was submitted for publication on April 19, 2024 at 07:35 CET.